Industrial Series

Clopay Industrial Series overhead doors provide a combination of performance and reliability for a range of industrial applications. For increased energy efficiency, polystyrene insulated insulation with a vinyl or steel backer, is available. These commercial doors offer an assortment of flush, ribbed or raised panel designs in a variety of colors, textures, windows and steel gauges. Ideal applications include warehouses, loading docks and industrial and agricultural facilities.

Models

| Model | Section Thickness | Panel Design | Ext. Steel Gauge | Backer | R-value* | Max Width** | Max Height |

| 520 | 2″ | Minor & Deep Ribs | 20 Gauge | N/A | N/A | 26’2″ | 20’0″ |

| 520S | 2″ | Minor & Deep Ribs | 20 Gauge | Pre-painted 30 gauge steel back cover | 6.6 | 26’2″ | 20’0″ |

| 522 | 2″ | Flush | 20 Gauge | N/A | N/A | 24’2″ | 24’0″ |

| 522S | 2″ | Flush | 20 Gauge | Pre-painted 30 gauge steel back cover | 6.6** | 24’2″ | 24’0″ |

| 524 | 2″ | Minor & Deep Ribs | 24 Gauge | N/A | N/A | 24’2″ | 20’0″ |

| 524V | 2″ | Minor & Deep Ribs | 24 Gauge | Polyethylene vinyl back cover | 6.6 | 26’2″ | 20’0″ |

| 524S | 2″ | Minor & Deep Ribs | 24 Gauge | Pre-painted 30 gauge steel back cover | 6.6 | 24’2″ | 20’0″ |

| 525 | 2″ | Minor & Deep Ribs | 25 Gauge | N/A | N/A | 20’2″ | 16’0″ |

| 525V | 2″ | Minor & Deep Ribs | 25 Gauge | Polyethylene vinyl back cover | 6.6 | 20’2″ | 16’0″ |

| 525S | 2″ | Minor & Deep Ribs | 25 Gauge | Pre-painted 30 gauge steel back cover | 6.6 | 20’2″ | 16’0″ |

| 664 | 2 1/8″ | Raised Panel Steel | 24 Gauge | N/A | N/A | 20’2″ | 16’0″ |

| 664V | 2 1/8″ | Raised Panel Steel | 24 Gauge | Polyethylene vinyl back cover | 6.3 | 20’2″ | 16’0″ |

*Calculated door section R-value is in accordance with DASMA TDS-163

Options

Insulated and Non-insulated doors come with a variety of options to address your building requirements. Options below are not available on all models. See model specific literature or consult a Clopay commercial dealer for option availability.

Design Options

- Windows

- 24″x6″

- 24″x12″

- Full View (pre-painted white or brown or clear anodized)

Color Options

Standard White

Almond

Desert Tan*

Sandtone*

Chocolate Brown

Commercial Tan

Gray

Trinar® White*

** Available on select models.

Performance Options

- High Cycle Springs (25K, 50K and 100K available)

- 3″ heavy duty track (where not standard)

- Outside keyed Security Lock

- Double End Stiles

- Design pressure rated (WindCode)

- Impact Rated

- Photo eyes, sensing edges and Operators

- Extended 8-Year Hardware Warranty

- Header (top) and Jamb Seals

- High Performance Hardware Upgrade

Custom Options

- Mullions

Construction

Model 520/524/525

| Panel Design: | 2″ thick roll formed ribbed steel | |

| Steel Gauge: | 20 ga (.034″ min) – Model 520, 24 ga (.022″ min) – Model 524and 25 ga (.019 min) – Model 525 ribbed steel sections | |

| Joint Design: | Tongue and groove | |

| Thickness/Insulation: | No insulation | |

| Hardware: | 14 gauge hinges, commerical 10-ball steel rollers, 10,000 cycle torsion springs | |

| Colors: | Pre-painted white or brown (520/525) Pre-painted white, brown, tan or gray (524) | |

| Limited Warranty: | 10-year finish against rust / one-year material & workmanship |

Model 520S

| Panel Design: | 2″ thick roll formed stucco embossed ribbed steel |

| Steel Gauge: | 20 gauge (.034″ min) for maximum dent resistance |

| Joint Design: | Tongue and groove |

| Thickness /Insulation | 1-3/8″ thick polystyrene insulation with pre-painted 30 gauge steel backcover |

| Thermal Conductivity | R-Value 6.6* |

| Paint System: | 3-stage paint process delivers maintenance free finish that resists rust perforation |

| Colors | Pre-painted white or brown |

| Limited Warranty: | 10-year paint / one-year material & workmanship |

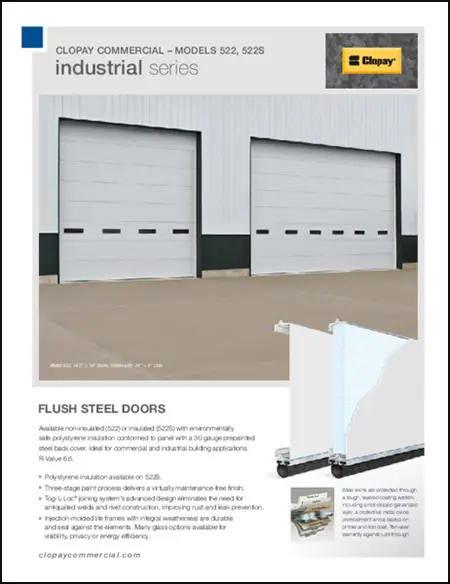

Model 522/522S

| Panel Design: | 2″ thick roll formed stucco embossed flush steel |

| Steel Gauge: | 20 gauge (.034″ min) for maximum dent resistance |

| Joint Design: | Tongue and groove |

| Thickness /Insulation | 1-3/8″ thick polystyrene insulation with pre-painted 30 gauge steel backcover |

| Thermal Conductivity | R-Value 6.6* |

| Paint System: | 3-stage paint process delivers maintenance free finish that resists rust perforation |

| Colors | Pre-painted white or brown |

| Limited Warranty: | 10-year paint / one-year material & workmanship |

Model 524V/524S

| Panel Design: | 2″ thick roll formed stucco embossed steel |

| Steel Gauge: | 24 gauge (.022″ min) ribbed steel sections |

| Joint Design: | Tongue and groove |

| Thickness /Insulation | 1-3/8″ thick polystyrene insulation with polyethylene vinyl backcover (524V) 1-3/8″ thick polystyrene insulation with pre-painted 30 gauge steel backcover (524S) |

| Thermal Conductivity | R-Value 6.6* |

| Paint System: | 3-stage paint process delivers maintenance free finish that resists rust perforation |

| Colors | Pre-painted white, brown, tan or gray |

| Limited Warranty: | 10-year paint /one-year material & workmanship |

Model 525V/525S

| Panel Design: | 2″ thick roll formed smooth steel with combination of deep minor ribs |

| Steel Gauge: | 25 gauge (.019″ min) |

| Joint Design: | Tongue and groove |

| Thickness /Insulation | 1-3/8″ thick polystyrene insulation with polyethylene vinyl backcover (525V) 1-3/8″ thick polystyrene insulation with pre-painted 30 gauge steel backcover (525S) |

| Thermal Conductivity: | R-Value 6.6* |

| Paint System: | 3-stage paint process delivers maintenance free finish that resists rust perforation |

| Colors: | Pre-painted white or brown |

| Limited Warranty: | 10-year paint / one-year material & workmanship |

Model 664

| Panel Design: | 1 7/8″ thick roll formed steel | |

| Steel Gauge: | 24 gauge (.22″ min) raised panel door | |

| Joint Design: | Tongue and groove | |

| Thickness & Insulation | No insulation | |

| Hardware: | 14 gauge hinges, commerical 10-ball steel rollers, 10,000 cycle torsion springs | |

| Colors: | Pre-painted snowmist white, chocolate, brown, almond, sandstone, or desert tan. | |

| Limited Warranty: | 10-year finish against rust through / one-year material & workmanship |

Model 664V

| Panel Design: | 1-7/8″ thick woodgrain embossed raised panel steel |

| Steel Gauge: | 24 gauge (.022″ min) ribbed steel sections |

| Joint Design: | Tongue-and-groove |

| Thickness /Insulation | 1-3/8″ thick polystyrene insulation with polyethylene vinyl backcover |

| Thermal Conductivity | R-Value 6.3* |

| Paint System | 3-stage paint process delivers maintenance free finish that resists rust perforation |

| Colors | Pre-painted white, brown, tan or gray; Trinar white or beige |

| Limited Warranty: | 10-year paint / one-year material & workmanship |

*Calculated garage door section R-value is in accordance with DASMA TDS-163.

Specs/Drawings

Model

BIM

Shop Drawing

Specs

Installation Manual

Warranty

Track and Jamb Drawings

Track/Jamb

Drawing

DXF

Brochures

Brochure Commercial Idea Book

At Clopay, we take form and function seriously. From blueprints to reality, our expert engineers design commercial doors that exceed expectations for performance and elevated style.

Brochure Model 520/520S

A great fit for industrial applications, models 520 and 520s deliver on durability and weather protection.

Brochure Model 524/524S

Weather-proof and durable, these doors are made with optional polystyrene insulation and an injection-molded lite frame with integral weatherseal for optimum protection.

Brochure Model 525/525S/525V

These rib-steeled doors come available in polystyrene insulated or non-insulated with our advanced Tog-L-Loc® design for rust and leak prevention.

Brochure Model 664/664V

Our contemporary-look Models 664 and 664V raised panel steel doors are available in both insulated and non-insulated options.

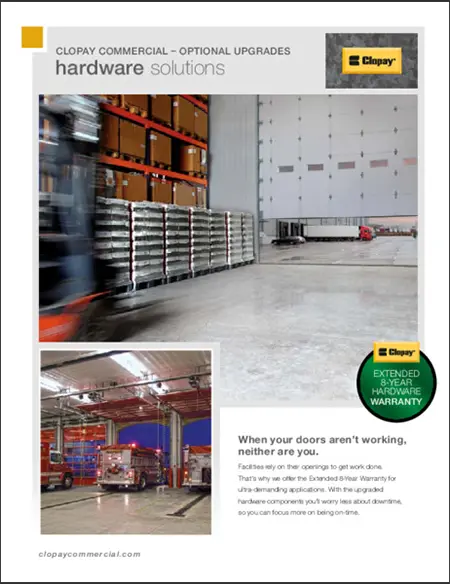

Extended 8-Year Hardware Warranty

Facilities rely on their openings to get work done. That’s why we offer an Extended 8-Year Warranty for demanding applications.

Brochure 522/522S

Our flush-steel doors are available with our environmentally safe insulation with a 30 gauge prepainted steel back cover.

Springs and Hardware

Commercial Hardware

Commercial doors are designed with hardware to meet demanding applications of commercial building usage. All commercial doors are provided with the following hardware as standard. For additional upgraded hardware see “Options” tab.

- 14 gauge hinges

- Commercial 10 ball steel rollers with options for nylon tire rollers

- 10,000 cycle torsion springs

- Steel step plate and lift handle for easy operation

- Inside slide lock for increase security

- 19 gauge steel hinge support plates

- 18-gauge single end stiles; 16-gauge double end stiles

- Galvanized aircraft cables with 7:1 safety factory

- 2” or 3” track in a variety of configurations to meet building design requirements

Commercial Track Applications

In commercial settings, space utilization and space constraints are important factors in choosing the correct hardware configuration for your application. Clopay track offerings and options enable you to make the most efficient use of available space. Options include standard lift, low head room front or rear mount, follow the roof pitch, full vertical or combination of these options. Learn more.

Commercial Torsion Springs

Designed to counterbalance even the largest doors, commercial torsion spring assemblies can be designed for Industry standard 10,000 cycles or can be upgraded to 25,000, 50,000 or 100,000 expected life cycles.

What We Offer

Residential

- Garage Doors

- Openers

Gates

- Automatic Gates

- Gate Operators

Access Control

- Doorking 1812 Classic

- Doorking 1835

- LiftMaster CAPXL

- Linear e3 Entry

- CellGate Watchman EVO

Don't just take our word for it!

EXCELLENTTrustindex verifies that the original source of the review is Google. Great job and fast service getting our roll up door replaced. Jesse was professional and the guys did a fantastic job. Thank you!Posted onTrustindex verifies that the original source of the review is Google. Tyler and Daniel were amazing. Fixed me up on the same day I called left the work area in better condition than what they walked into. Cheers to these 2 gentsPosted onTrustindex verifies that the original source of the review is Google. Tyler Westfall and Matt Sims were out to install a new roll up door for our company and they were amazing! Prompt, polite and clean and did the job fast! We’d hire them again in a heartbeat! The door looks and works amazing!Posted onTrustindex verifies that the original source of the review is Google. Today Dillion Z and Jesse G came to replace our Industrial Bay Roll up Door. They were prompt, professional and I am forever grateful that they fixed our door! I park inside during the day and have my "garage" back. It was a huge job and they did fantastic work!!!!!!! By the way, they also left it very clean! THANK YOU BOTH!!!Posted onTrustindex verifies that the original source of the review is Google. Freddy and Jesus were extremely efficient, competent, courteous and diplomatic (our garage is a mess. They pretended not to notice!) We are very pleased with their work and products!Posted onTrustindex verifies that the original source of the review is Google. I recently had the pleasure of working with R&S Doors and Gates in Sacramento once again, and we couldn't be more satisfied with their service. We recently moved into a new home and since we used R&S to replace our garage system at our old house … when we saw them at the home show we knew we needed them to come back out to our new place!! From start to finish, the experience was nothing short of excellent. Johnnie L. and Dillion Z. arrived right on time, showcasing their professionalism and dedication to customer satisfaction. They conducted a thorough assessment of the situation and ensured everything was in perfect working order. Their attention to detail and commitment to quality really stood out. It's evident that R&S is a company that takes pride in their work, and this is why I chose to use them again. Having worked with them before, I can confidently say that their consistency in delivering great results is commendable. Everything is up and running smoothly, and I couldn't be happier with the outcome. If you're in need of garage door and gate services, I highly recommend R&S Doors and Gates. You won't be disappointed!Posted onTrustindex verifies that the original source of the review is Google. Tyler James and their team did a great job on our overhead doors. They move really quick and remain safe while working on the project. We would definitely hire R&S to do our projects in the futurePosted onTrustindex verifies that the original source of the review is Google. Great company. Tyler is a great tech got my roll up door replaced within the day.Posted onTrustindex verifies that the original source of the review is Google. Great experience with the fellas, they stayed an extra hour in the rain to make sure the doors were installed. Highly recommend.Posted onTrustindex verifies that the original source of the review is Google. James is awesome

Our service areas

Proudly serving in:

- Sacramento County

- Yolo County

- Placer county

- El Dorado County

- Nevada County