Overview

Republic Doors and Frame’s complete line of commercial hollow metal embossed panel doors provide a wide range of design flexibility for your architectural needs. Whether you select a traditional design or a high definition (HD) design, you will be adding a beautiful entrance to any architectural opening with rich, distinctive panel embossments. Republic’s traditional embossed designs include 8, 6, 4, 2, and 1 panel layouts. We also offer 8’0 (nominal) tall on the 6 and 2 panel designs with elongated panels. Several of our designs are available with provision(s) for lite inserts. Our doors are available in 20, 18 and 16 gage, depending upon design. Embossed doors are standard A40 galvanneal with polystyrene core.

Features and benefits

- Steel door performance with decorative designs

- SDI levels 1-3

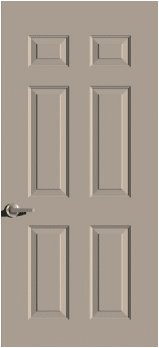

- Traditional designs include 6 panel

options:

− 1 ¾” Or 1 3⁄8″ thick design, rated for light to extra-heavy duty use

− 8 Foot with elongated panels

− STC 40 (STC hardware included) - Minimum sizes 2’8″x 6’8″ available

- Certified for 3 hours of fire protection tested in accordance with UL 10b, UL 10c, UBC 7-2, and ASTM e152

- 2 And 6 panel embossed doors are ideal for hurricane applications and hold a pressure rating of 80 psf for both inswing and outswing applications.

Traditional designs

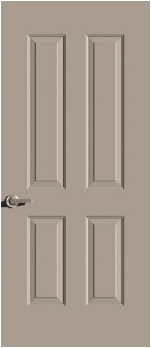

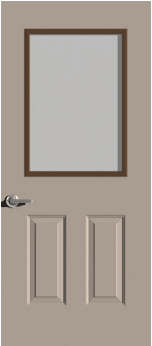

4 panel

6 panel

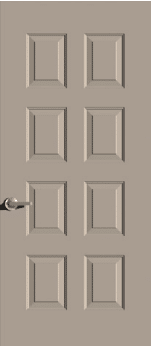

8 panel

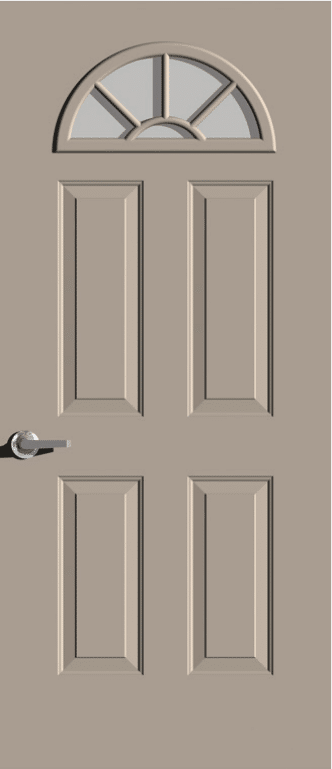

Half glass

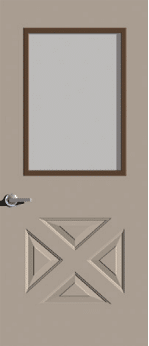

Cross buck

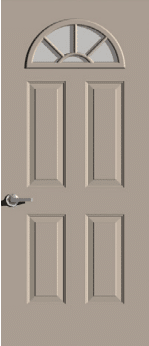

Sun burst

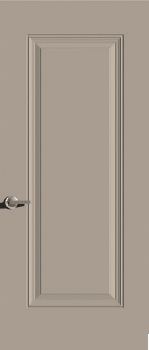

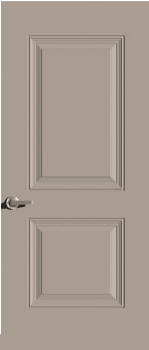

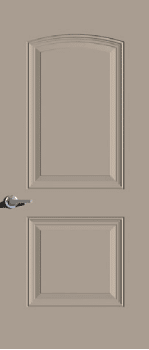

High definition designs

1 panel

2 panel

2 panel archtop

Additional standard product features

- Hinge channel is non-beveled and reinforced with a full height 16 gage steel channel projection welded at a maximum of 5″ on center with an

additional 9 gage reinforcement plate at each hinge location, providing over 3⁄16″ total reinforcement. - 16 gage flush top and inverted bottom channels projection welded to both

skins every 2 1⁄2″ on center. - Lock edge is non-beveled and reinforced with a continuous 16 gage channel, mortise and cylindrical lock reinforcements are integral 16 gage

reinforcements. - Doors are thoroughly cleaned, phosphatized and primed with a coat of force cured rust inhibiting primer that meets and/or exceeds the

requirements of ANSI A250.10 (120 hour continuous salt spray test per ASTM B117 and 240 hour continuous humidity test per ASTM D4585) - Due to availability, certain sizes, patterns may require minimum quantity

purchases