Special-Lite FRP Door

FRP doors: Unmatched durability and lasting value

Special-Lite Fiberglass Reinforced Polyester (FRP) Flush Doors offer trouble-free performance and long-lasting beauty in the most demanding interior and exterior entrance applications. Remarkably durable, they can withstand heavy traffic, abuse, or adverse environmental conditions—and continue to look like new for years. Our SL-17 FRP Doors are the informed choice for schools, public buildings, water and wastewater treatment facilities, and other applications that quickly damage or even destroy lesser doors. They also offer an economical, easy-to-clean alternative to stainless steel for sanitary environments such as hospitals, laboratories and kitchens. Whether for new construction or for retrofit applications, FRP Flush Doors from Special-Lite deliver the highest performance, longest life, and greatest overall value.

Select the model that suits your needs

For problem entrances or challenging environments, you can’t beat the supertough SL-17. In cleanroom applications, the SL-17 can be specified with sealed seams, closed top and bottom rails, and foam-filled stiles and rails. Correctional or institutional toilet and shower door requirements call for the SL-175, a smaller version of the SL-17. When an entrance is not expected to see deliberate abuse or vandalism, consider the SL-20 FRP Door. It features the same construction as the SL-17 with a smooth, painted FRP face sheet that can be finished in any of our paint colors, or your own custom color. No matter which FRP door is right for your application, when you consider true product lifetime cost, Special-Lite FRP Flush Doors are the first choice for lasting value. Special-Lite offers the SL-21 Fire-Rated FRP-Clad Door, which is the perfect complement to our FRP Doors for interior applications that require a 90-minute fire door. Tested in accordance with UBC 7-2, NFPA 225, and UL 10C requirements for interior applications, the SL-21 has passed the 1-1/2 hour positive pressure test, hose stream test, and 250°F (121°C) temperature rise tests to achieve Warnock Hersey listing for fire-rating applications in the United States.

Why a heavier, more rigid door isn’t a more durable door

Conventional wisdom says that a heavier, more rigid door is a stronger door. We say that employing sound engineering principles results in a lighter door that’s actually a better door. Heavy, rigid doors subjected to severe use and abuse place high loads on hardware and framing. Installing heavier hardware isn’t the solution, though, because it simply increases the weight of the door, stressing hardware and framing all the more. The result is eventual entrance failure. In contrast to the Heavier is Better philosophy, we make Special-Lite Doors as light as possible. We give them a high degree of flexibility and fatigue endurance to absorb the forces involved and prevent structural degradation over time. Less door mass not only means reduced wear and tear on hardware and framing for longer entrance system life, but reduced opening effort as well. But don’t confuse lightweight with light-duty. All Special-Lite Doors are heavy-duty doors, and should only be compared to other heavy-duty doors.

FRP face sheets reduce maintenance requirements

Special-Lite FRP Doors look great for years with only routine cleaning using mild soap and water. Unlike metal or wood doors, they will never rust, corrode, crack, split, peel, or rot. With FRP face sheets the color goes through and through so scratches won’t be obvious. Some of our FRP face sheets can also be painted. FRP doors made with Special-Lite’s exclusive SpecLite 3® FRP face sheets are even more amazing. SpecLite 3® FRP is scratch, scuff, and fade resistant and will never need painting. Compare that to the requirements of hollow metal doors, where you have to paint them before you can even hang them, and periodically forever after.

Better materials and designs for better doors

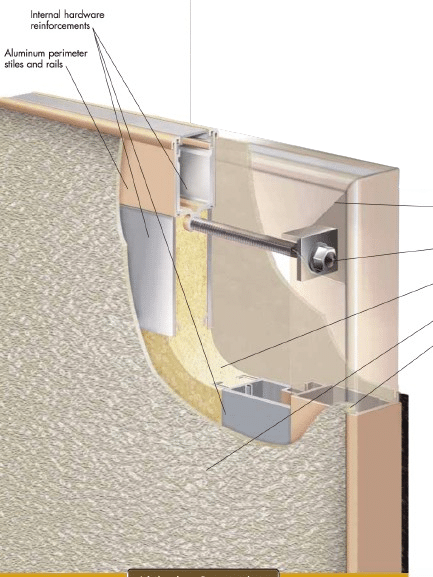

Special-Lite FRP Doors have been solving the toughest entrance challenges since the early 1980’s, when we pioneered the application of FRP on doors. Today, we are the leading volume producer of FRP doors. Our FRP Flush Doors are manufactured with stiles and rails of extruded 6063-T5 aluminum alloy, sized and configured for maximum strength without unnecessary, non-functional bulk. All anodized finishes are Class I (.7 mil) to ensure long-lasting beauty with only routine cleaning using mild soap and water. Stiles and rails are joined with mitered corners and angle blocks secured by 3 ⁄8″ diameter full-width galvanized steel tie rods. The tie rods run through integral splines in the top and bottom rails, effectively making the tie rod a part of the rail. This method of construction provides the necessary flexibility to withstand abuses that would cause a mechanically-joined or welded corner to fail.

At the core of our door’s strength is our door’s core

The poured-in-place urethane core of our SL-17 and SL-20 Doors is not just a passive filler—it’s a functional component that contributes significantly to the durability of Special-Lite Doors. After the door has been completely assembled, the core material is injected using our proprietary foam injection technology, ensuring a complete fill with a minimum five pounds per cubic foot density. This strong, lightweight, structural urethane foam bonds firmly to the rails, stiles, reinforcements and face sheets to transform the door into a solid, completely sealed unit with incredible impact resistance and flexural strength. Our urethane foam won’t absorb or be damaged by water. It’s also totally CFC- and HCFCfree to protect the environment.

Tested tough in the real world, tested tough in the lab

We’ve built a reputation for building doors that survive for decades in the toughest imaginable application—schools. That should be proof enough of their durability, but we weren’t content to leave it at that. We hired an independent testing laboratory to simulate many hard lifetimes worth of opening and closing cycles to see just how much our doors could really take. After 25 million cycles, the door showed no signs of excessive wear or fatigue. Our SL-17 Door has passed a host of other industry standard tests as well, including Dade County, Florida hurricane impact tests. Contact Special-Lite for detailed test results.

All Special-Lite FRP face sheets are .120″ thick for great impact strength. Face sheets are rabbeted and secured on all four sides by full-length integral reglets on the edges of the stiles and rails to form a truly flush door. Securing the face sheet continuously on four sides without troublesome screw-applied capping is only possible with mitered corner joinery. Of course, it’s definitely more difficult to manufacture doors this way, so other door makers don’t do it. But the fact that it results in a more durable door is all the reason we need. Standard and optional internal reinforcements provide secure attachment for the exact hardware specified. We can supply doors with hardware installed, or reinforced and prepped for field installation of hardware.

- Mitered corner joints secured by angle blocks

- Full-width 3 ⁄8" galvanized steel tie rods

- Poured-in-place urethane core

- .120 fiberglass reinforced polyester face sheet

- Face sheets rabbeted into integral reglets on stiles and rails

Sustainable by design— for better quality of life

GREENGUARD Certified for better indoor air quality

Exterior doors may not be the first thing you think of with respect to indoor air quality (IAQ), but the fact is that one side of every exterior door is inside, and can impact IAQ. In addition, the corrosion resistance and durability of our FRP doors make them ideal in pool areas, locker rooms, and showers, which are clearly interior locations. Special-Lite’s FRP Doors* are the first doors of any kind to be GREENGUARD Indoor Air Quality Certified® , including the stringent new GREENGUARD Standard for Children & Schools™ . Modeled on the characteristics of the classroom environment, this new standard is the toughest to date. GREENGUARD Certification provides independent assurance of IAQ performance.

Easy-care finishes reduce maintenance costs and health risks

Ongoing maintenance also has an impact on IAQ. Special-Lite’s maintenancefriendly finishes eliminate the regular sanding and repainting necessary with hollow metal or wood doors, which produce potentially dangerous airborne particulates and fumes. And thanks to the durability of our stain-resistant finishes, even tough stains like graffiti can be removed from our products with green cleaners that won’t degrade IAQ.

Better thermal performance helps reduce energy usage

The thermal efficiency of the building envelope has never been more important. Using Special-Lite FRP Doors can help reduce heating and cooling loads. Independent laboratory testing confirms that Special-Lite FRP Doors, with a minimum R-value of 3.45, provide superior thermal insulating properties compared to published claims from the makers of hollow metal doors.

Delivering lowest lifecycle cost

Special-Lite FRP Doors are specifically engineered and manufactured to provide the longest possible service life with minimal maintenance, even in the most demanding applications. Higher quality materials, advanced manufacturing technology and long lasting finishes deliver the lowest possible lifecycle cost when compared to hollow metal, wood, or even other FRP doors.

Add your own finishing touches

Each Special-Lite Door is made to order

Every door and frame we make is a custom solution, made to order. We can do what it takes to bring your design ideas to life with the right entrance system to suit your application. We can even provide you with submittal drawings or computergenerated design renderings to help with the specification and design process. Unique configurations such as arched doors and transoms, odd sizes, unequal pairs, monorail cut-outs, dutch or bi-fold doors, and custom lites are no problem for our experienced craftsmen. We can make SL-17 FRP Doors as large as 80″ wide x 216″ tall, or as small as 12″ by 12″.

A rainbow of color choices, and custom options, too

We offer a wide range of color choices for our entrance products. A variety of through-molded color choices are also available in our SpecLite 3® FRP face sheets. Or if you prefer a custom color, our non-SpecLite 3® FRP face sheets can be painted to match any Kynar® paint or any customer-specified color. Anodized aluminum is available in standard clear, dark bronze, and black, or optional champagne, light bronze, and medium bronze. We also offer 20 established Kynar® paint colors, or we can match any custom color.

Security grates and vandal screens

Security grates can protect lites in extreme environments, while our vandal screens protect against casual abuse. Additional information can be found in our Hardware & Lites brochure.

Hardware

Special-Lite manufactures a selection of removable mullions, push bars, and pulls, including flush pulls that improve entrance safety and security. For additional information regarding our line of hardware, see our Hardware & Lites brochure.

Vision lites

Special-Lite Vision Lites may be specified with 1 ⁄4″, 1 ⁄2″, or 1″ glazing. We can supply vision lites in custom sizes, shapes, and colors to suit your specific requirements. Aluminum surface-applied muntins in 1 ⁄2″ and 11 ⁄4″ widths are also available, allowing you to create just the look you want. Custom vision lites may be specified in any size or configuration, subject to the following guidelines:

- Consult the factory when total vision lite area exceeds 50% of the foam area.

- To avoid hardware conflicts, vision lites should be located at least 8" from the top, 12" from the bottom and 7" from the sides of the door.

Glass can be factory-installed or installed in the field. Rectangular vision lites are furnished with aluminum glass stops. Curved lites are typically glazed with black EPDM gasket, but may be available with aluminum glass stops. Consult the factory for details.

Louvers

Louvers factory-installed in doors are subject to the placement and size guidelines that apply to vision lites. Insect screens are an available option and must be specified. Louvers are also available for side lite and transom applications.

Simplify your life with entrance solutions from Special-Lite

A complete entrance from a single source

Special-Lite manufactures complete entrance solutions—doors, frames, and panels. Enjoy the convenience, reliability and performance advantages of having a complete, ready-to-install entrance supplied by a single source, delivered to the job site in a single, on-time shipment. Single-sourcing ensures proper door and frame fit, correct hardware operation, exact finish match, and longer entrance life. We can even ship doors with hardware and glazing installed, significantly reducing expensive job site labor and installation time, and preventing last-minute problems.

Simplify field installation with factory-applied hardware

Special-Lite will apply hardware at no additional charge beyond hardware prep charges. Factory-installed hardware not only fits better, but the installation is warranted not to come loose under normal usage for a full 10 years. If you prefer, we can simply prep for field installation of hardware. We can supply thresholds shipped loose for field installation. All doors are shipped in special flotation cartons that protect any installed hardware. Surface-applied door closers and surface-applied sweeps must be installed in the field.

A simple warranty that works

To help simplify your life we stand behind our products with an uncomplicated, 10-year, 100% parts and labor warranty. Ask your sales representative for a copy of our warranty statement, and compare it to what other supplier warranties actually cover after all of their exclusions and limitations. You’ll see that when you specify Special-Lite, you’re really covered.